1. Barrera térmica aluminizada

Definición :Un material diseñado para reflejar el calor radiante, generalmente compuesto de un sustrato (por ejemplo, fibra de vidrio, poliéster o cerámica) recubierto con una capa de aluminio.

Función La capa de aluminio refleja hasta el 90 % del calor radiante, mientras que el sustrato proporciona aislamiento y durabilidad. Protege los componentes de las altas temperaturas bloqueando la transferencia de calor.

Aplicaciones :

Automotor :Compartimientos del motor, sistemas de escape.

Industrial :Maquinaria, tuberías, sistemas HVAC.

Construcción : Áticos, techados, aislamiento de paredes.

Instalación :Requiere sujetadores mecánicos (clips, tornillos) o cintas resistentes al calor.

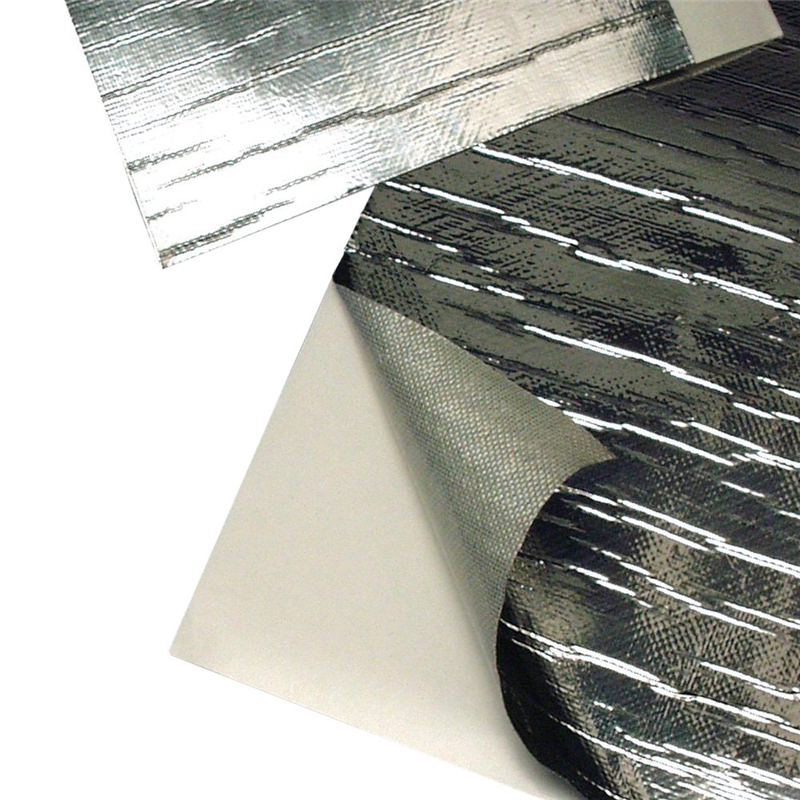

2. Barrera térmica aluminizada con respaldo adhesivo

Definición :Similar a la barrera estándar, pero incluye una capa adhesiva resistente al calor en un lado para una fácil fijación.

Función Combina la reflexión del calor con una instalación simplificada. El adhesivo está diseñado para soportar altas temperaturas sin degradarse.

Aplicaciones :Ideal para superficies donde no es posible perforar ni colocar sujetadores, como piezas de motor curvas, gabinetes electrónicos o conductos.

Instalación :Aplicación pelable y adhesiva; requiere superficies limpias y secas para una adhesión óptima.

Consideraciones clave

Materiales La elección del sustrato (p. ej., fibra de vidrio para mayor durabilidad, poliéster para mayor flexibilidad) afecta el rendimiento. El recubrimiento de aluminio puede depositarse por vapor para obtener capas delgadas y uniformes.

Resistencia a la temperatura :Por lo general, soporta temperaturas de -40 °F a 1500 °F, dependiendo del sustrato y la calidad del adhesivo.

Seguridad : Los sustratos como la fibra de vidrio pueden requerir el uso de guantes durante su manipulación. Los adhesivos deben ser atóxicos y de baja emisión de vapores al calor.

Ventajas :

La reflexión efectiva del calor reduce el estrés térmico.

Ligero y flexible para un uso versátil.

La versión adhesiva ahorra tiempo de instalación.

Limitaciones :

El adhesivo puede fallar bajo condiciones de calor o humedad extremos si no es de alta calidad.

Mayor costo en comparación con el papel de aluminio básico.

Ejemplos :

Automotor : Escudos térmicos cerca de los colectores de escape.

Uso doméstico :Aislamiento reflectante en áticos.

Industrial :Envoltura de hornos o calderas industriales.

En resumen, las barreras térmicas aluminizadas son esenciales para controlar el calor en entornos de alta temperatura, y la variante con respaldo adhesivo ofrece comodidad para aplicaciones específicas.